Metal fabrics solution

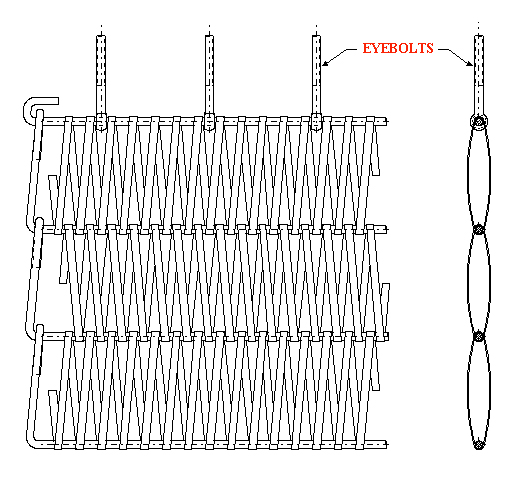

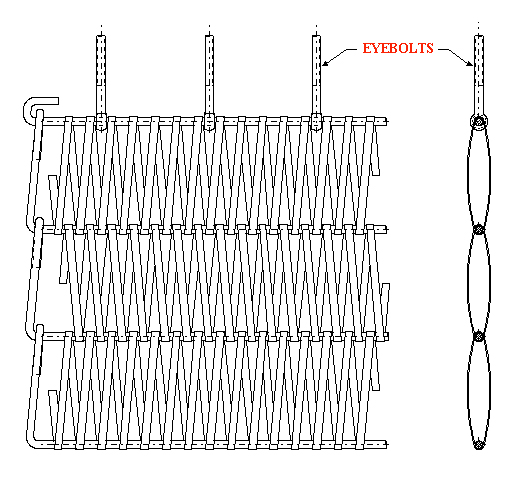

This system of metal fabrics was developed specifically for fixing and parking structures where tension loads require consideration. At the top, bottom and intermediate locations. The top round bar is inserted into brackets. Any intermediate round bars are connected to pivoting brackets for lateral support. Springs attach to the bottom bar in order to apply proper pre-tension to the mesh and to reduce the tension force on the structure. Eyebolts are attached to the springs to allow for maximum adjustability

|

Eyebolt

Specific to the flat spiral mesh products. An eyebolt is attached to the cross rod of the product and is tensioned by turnbuckle or nut. The eyebolt can be substituted with a hook. |

|

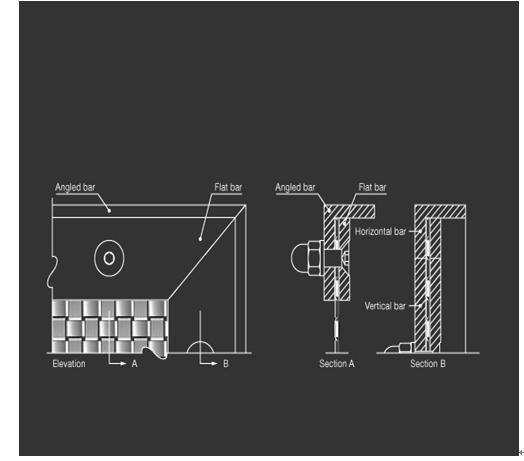

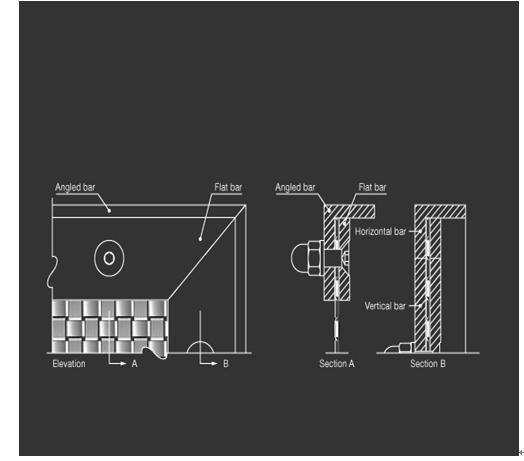

Frame

This rigid frame requires attachment to a substructure. The metal fabric is clamped tight by bolts into a frame made of flat and angled bars. Various bar profiles can be considered. Pre-crimped fabrics can also be welded to frames. Metal Fabric mesh is not tensioned in this construction and to assure flatness. |

|

Extended loop

Cables extend beyond the fabric edge to form a loop that is secured by a loop clamp. A round tensioning bar is threaded through the loops. Frequency of loops depends upon tension load. Loop diameter is determined by the size of the tensioning bar. |

|

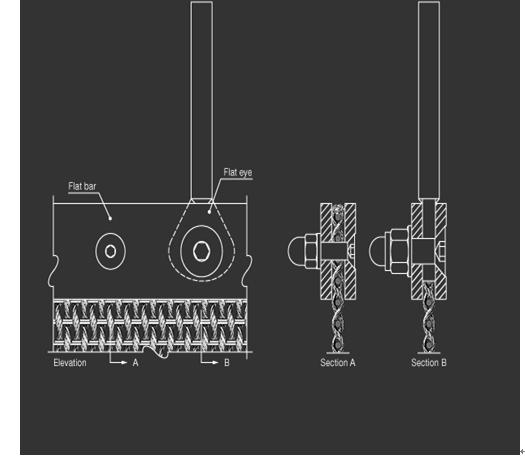

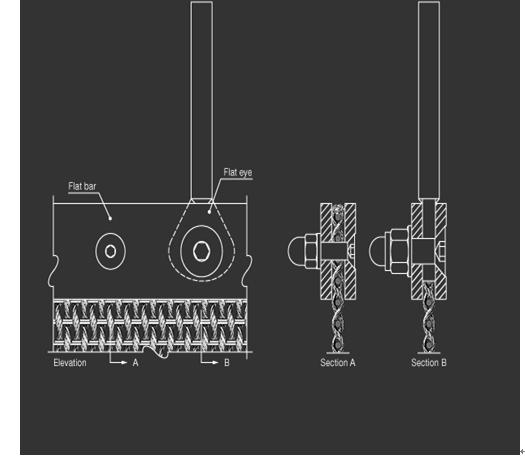

Flats with flat eye

Both ends of the fabric are clamped by flat bars. Flat eyes are then bolted in between the flats for tensioning by turnbuckles or nuts. Shown with RMJ-4510 |

|

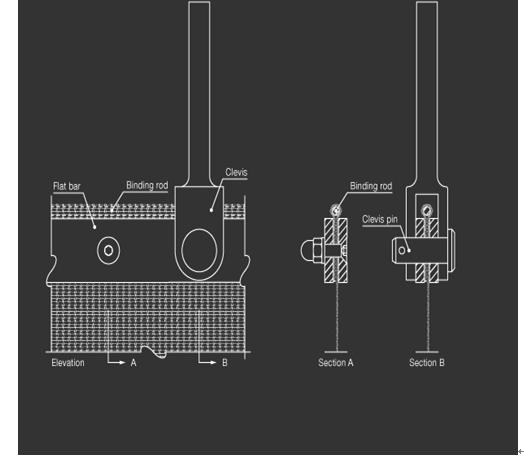

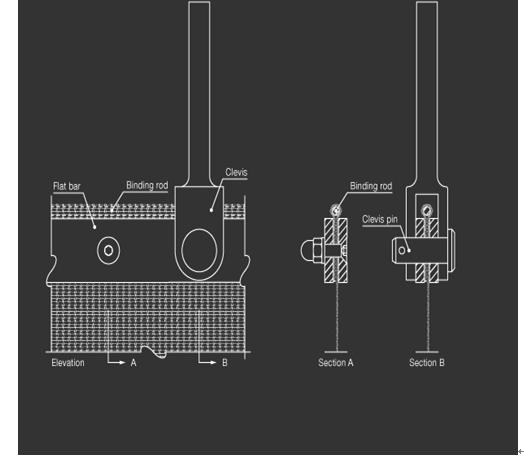

Flats with clevis & binding rod

The fabric is folded over a binding rod and clamped by flat bars at each end of the panel. Clevises with threaded rods are added for tensioning by turnbuckles or nuts. This is used only for fine mesh fabrics. |

|

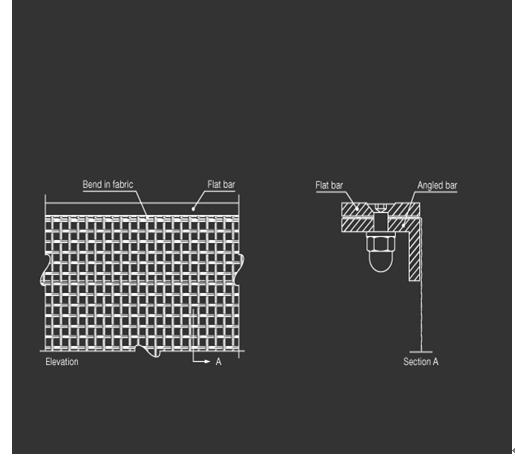

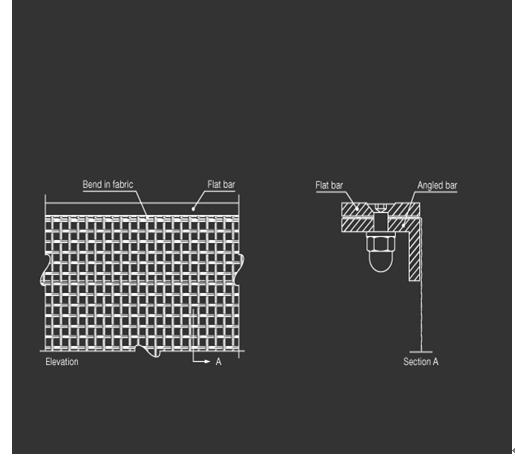

Frame with bent fabric

Typically used for flexible fabrics, where the cables are oriented in a horizontal direction, for applications such as column claddings.The rods of the fabric are bent at a right angle and are clamped by bars to form a rigid frame. |

|

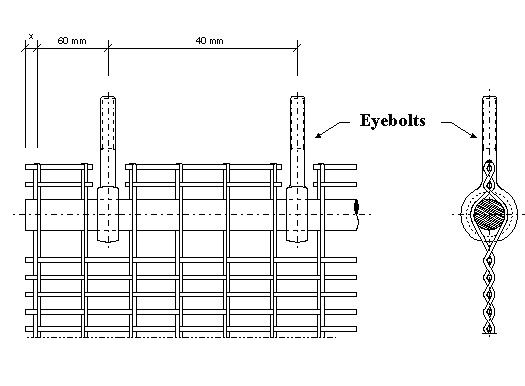

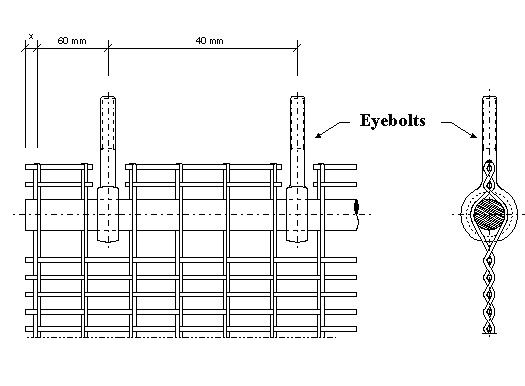

Woven-in bar with eyebolt

A round bar is inserted into the fabric in place of weft wires. Eyebolts are attached to the round bar for tensioning by turnbuckles or nuts. The size of the round bar and frequency of the eyebolts is determined by tension load. |

|

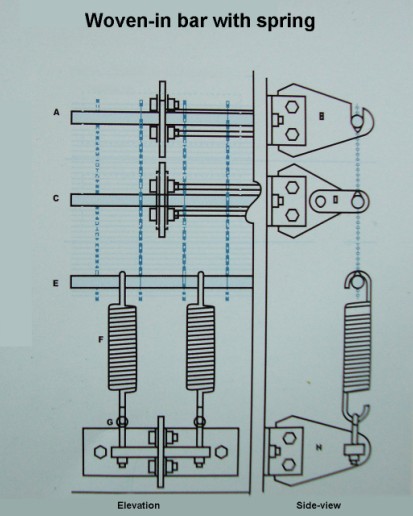

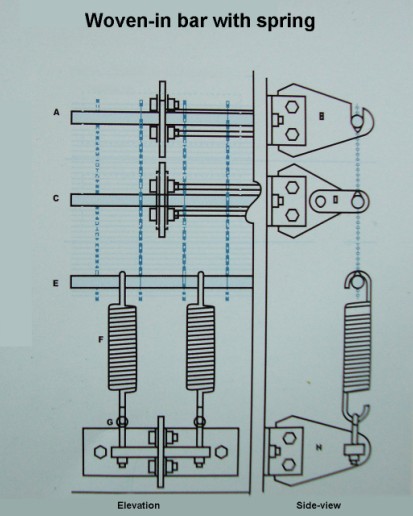

Woven-in bar with spring

This system was developed specifically for façades and parking structures where tension loads require consideration. Round bars are inserted into the fabric in place of weft wires at the top, bottom and intermediate locations. The top round bar is inserted into triangular brackets. Any intermediate round bars are connected to pivoting brackets for lateral support. Springs attach to the bottom bar in order to apply proper pre-tension to the fabric and to reduce the tension force on the structure. Eyebolts are attached to the springs to allow for maximum adjustability. |

|

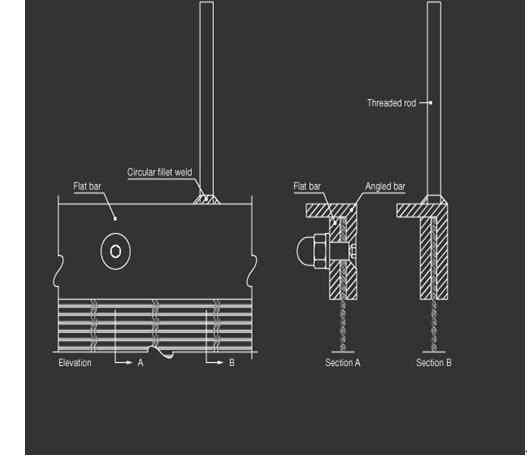

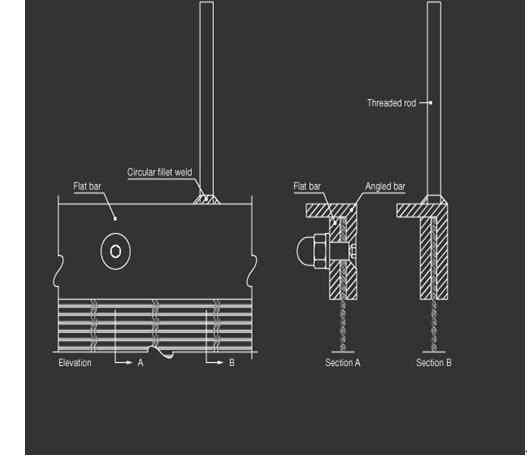

Flat & angle with threaded rod

Both ends of the fabric are clamped by the flat and angled bars with a threaded rod welded to the angle bar for tensioning by turnbuckles or nuts. Other bar profiles may be considered based on desired appearance. |

Also, we will invent new accessories according to the situation of installation place.